AS-540TL

Windows XP embedded + 17" touch screen operating system, easy to learn and operate with user-friendly screen design.

Network transmission function : In addition to the traditional USB interface transmission, built-in WIFI wireless network transmission or can be connected to a local network cable installed with a reversible wire motor makes it easier to replace the wire and break the wire, saving time and cost.

The X,Y axis can be optionally equipped with a linear scale with a minimum resolution of 1um, and the fully closed loop system is different from the previous open loop system which uses encoder feedback.

In terms of machine : Due to the different levels of casting, processing, assembly and parts used, our machine accuracy has been stable and reliable for a long time.

Easy to learn, efficient, economical, and officially licensed drawing software

With the new PW expert circuit system, the efficiency is increased by more than 30%...

X,Y-axis AC servo motor + linear slide + ball screw, standard with hand wheel control box, more convenient machine operation, faster movement and more accurate displacement.

Wire cutting machine is mainly composed of three parts: machine tool, digital control system and high frequency power supply. It is capable of cutting materials such as high strength, high toughness, high hardness, high brittleness, magnetic materials, as well as precise, small and complex shaped parts. Based on processing accuracy, ease of operation, labor saving and extended service life, it has undoubtedly influenced the popularity of the machine and its widespread use. Translated with www.DeepL.com/Translator (free version)

|

Item |

Unit |

AS-430HL |

|

WORK TABLE(L*W) |

mm |

495×595 |

|

MACHINE TRAVEL (X*Y) |

mm |

320×400 |

|

WORKPIECE THICKNESS |

mm |

240 |

|

CUTTING TAPER |

mm |

±3°/80 |

|

WORK TABLE LOAD |

kg |

300 |

|

MACHINE DIMENSION |

mm |

1160×1520×2050 |

|

MACHINE WEIGHT |

kg |

1700 |

|

CUTTING CURRENT |

A |

8 |

|

RATE POWER |

KVA |

3 |

|

VOLTAGE |

V |

220/380/415 |

|

CUTTING SPEED |

(mm2/min) |

140 |

|

WORKPIECE ACCURANCY |

mm |

≦0.015OCTAGONAL12*35(Octagonal) |

|

FINE ROUGHNESS RA |

(um) |

1.0 |

|

MOLYBDENUM RANGE |

mm |

0.18~0.20 |

|

LENGTH OF STORAGE DRUM |

mm |

210 |

|

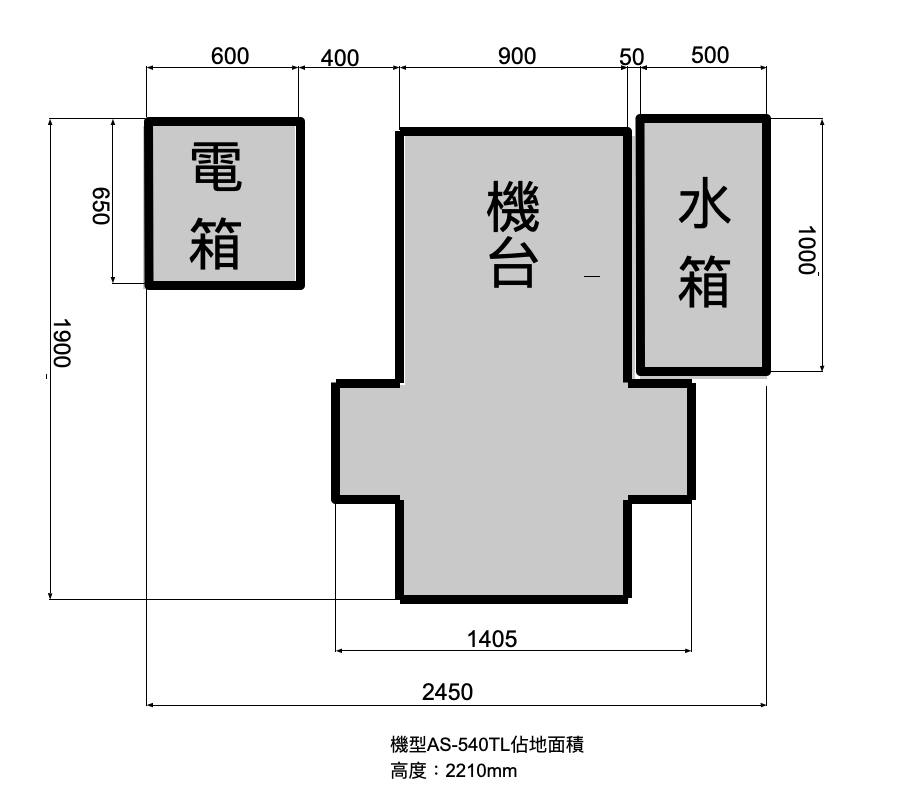

Generator Dimension |

mm |

600×650×1850 |

|

GENERATOR WEIGHT |

mm |

230 |

|

WORK TANT DIMENSION |

kg |

800×530×350 |

|

FLUID TANK DIMENSION |

mm |

500×1000×800 |

|

FLUID TANK CAPACITY |

(L) |

150 |

|

LED WORKING LAMP |

1PCS |

|

TOOLBOX AND WORKPIECE FIXTURE |

1SET |

|

TENSIONING WHEEL |

1PCS |

|

DISASSEMBLY GUIDE WHEEL TOOL |

1PCS |

|

Manual oiler |

1PCS |

|

MOLYBDENUM WIRE VERTICAL CORRECTION DEVICE |

1PCS |

|

MOLYBDENUM WIRE 0.18MM |

1ROLLS |

|

Cutting fluid18L |

1BARREL |

|

GUIDE WHEEL AND BEARING |

2SETS |

|

OPERATION MANUAL |

1PCS |

LINEAR SCALE AND DISPLAY COUNTER

Diamond Guider